Group 6

Nonlinear Dynamical Analysis of Ferrofluid

Objective

Ferrofluids exibit nonlinear dynamical behavior in response to both static and oscillating external magnetic fields. An experiment will be conducted to induce such a response using a Helmholtz-coil. The apparatus will be configured such that a single peak will be isolated, and observed with a high-speed camera. First a static magnetic field will be applied. This is expected to result in nonlinear surface behavior accompanied by a hysteresis effect. Spontaneous peak formation will be observed (Rosenweig instability) at a critical field magnitude. We will examine this response and relate an established qualitative model. The objective of this proposal is to stimulate a small drop of ferrofluid with a DC magnetic field so as to create a single fluid peak, and observe the effects on the height of the peak and the resulting bifurcation in height as a function of magnetic field strength. Furthermore, we will incrementally increase the temperature of the fluid above room temperature and observe the effect on the bifurcation parameters. The model for this system has been shown to agree with experiment, however, we will aim to add a thermal parameter that will theoretically account for the change in height as the temperature is varied and any changes in the resulting bifurcation diagram.

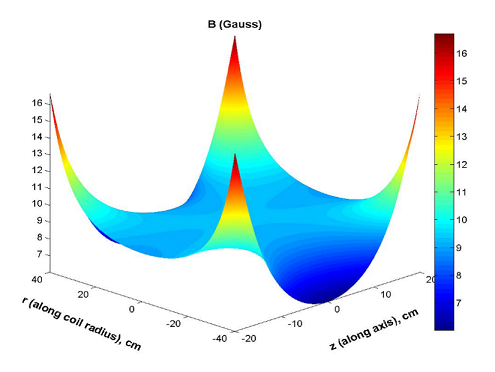

Figure 1. The calculated B-field through the center of the Helmholtz coil. The peaks represent the locations of coils, where the magnetic field is expected to be greatest. Notice the light blue region, which shows the uniform magnetic field (flat area) that passes through the center of the coil.

Hypothesis

We hypothesize that the peak height, h, of the fluid can be controlled by adjusting the static magnetic field strength, H0, and that the dependence of height on this field strength will, upon exceeding some critical field strength Hc, exhibit a subcritical pitchfork bifurcation. The solution h = 0 will no longer be stable, and the fluid peak height will jump to a value greater than zero upon increasing the strength.

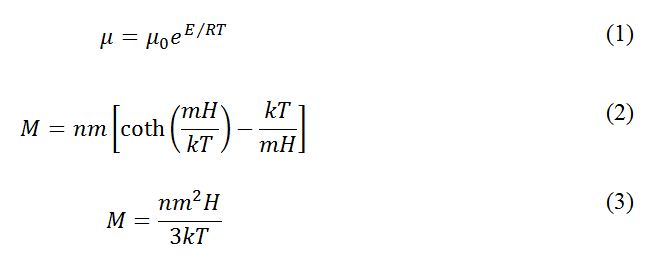

Secondly, increasing the fluid temperature will exponentially decrease the fluid viscosity[3] in accordance with the Arrhenius relation (1), but will also decrease its magnetization according to Langevine’s formula (2)[4, 5]. After a Taylor series expansion for small values of H, the magnetization M can be approximated by (3).

(see terms in appendix)

We expect the viscosity to drop off quicker than the magnetization, which goes with the inverse of temperature. Therefore, we hypothesize that as temperature is increased, the lower viscosity will dominate the lower magnetization, leading to a lower critical field strength and subsequent leftward shift – to lower H0 values – of the bifurcation point.

Background

The formation of ferrofluid liquid crests due to magnetic induction was first explored in seminal work by Cowley and Rosensweig in 1967[6]. They provided a theoretical basis for the critical level of magnetization for the onset of the instability at which peaks form and coined this phenomenon the “Rosensweig instability”. They validated the theory with experimentation by providing a uniform magnetic field, via a Helmholtz coil pair, to a small amount of fluid located between the coils. Oddly, the induced peaks were hexagonal in shape, and measurement of the distances between the peaks showed a close comparison to theoretical predictions. Furthermore, their work showed that the instabilities were governed by the stabilizing gravitational force and interfacial tension, which agreed with established knowledge of these systems[7]. Since then, ferrofluids have been shown to have interesting nonlinear behavior in the presence of magnetic fields as drops on a surface[1], fluid pumped under magnetic stress[8, 9], single[2] and multiple[10] peak formation in standing and oscillating magnetic fields, and propagation of these waves under temporally and spatially modulated magnetization[11]. Ferrofluids are ideal for a range of applications, including electronic devices to prevent debris accumulation in hard drives, mechanical applications for reducing friction between parts, aerospace, instrumentataion, and medicine, to name a few. Ferrofluids also provide many ideal characteristics for studying their surface instabilities. One includes the fluid’s colloidal and thermal stability. The magnetic particles remain in suspension, without agglutinating and precipitating out of solution. This is facilitated by thermal energy (Brownian motion) but is largely due to a surfactant coating on each particle that prevents the particles from permanently binding to each other[12]. The thermal stability has also been documented. Over several weeks of maintaining the fluid at temperatures above 150°C in seals jars, ferrofluids show minimal change in viscosity and magnetic permeability at 27°C before and after heating[6]. Furthermore, ferrofluids are typically capable of responding to a magnetic field in temperatures ranging from -55°C (outer space) and 200°C.

Experiment

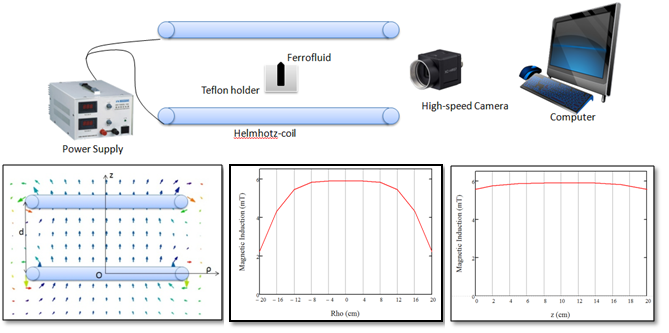

Overall Apparatus

The overall apparatus will consist of the following parts list and configured according to Figure 1(A). The Teflon fluid holder is used to obtain a flat fluid surface, taking advantage of the low surface tension of the material. The Teflon holder will be fabricated by drilling a 3mm diameter and 12mm deep hole into the bulk Teflon and then creating a 30 degree countersink. The ferrofluid is then injected into the hole. The current controlled power supply will drive the magnetic field generated within the Helmholtz-coils and the event monitored using a high-speed camera. Computer software will be used to correlate the height of the peak by a pixel/length relationship. The parts list follows: Helmholtz-coil – Welch (supplied), Teflon Fluid Holder (on order), 30A current controlled Power Supply (supplied), High-speed Camera (supplied), Ferrofluid – Ferrotech EFH-1 (supplied), magnetic field meter (supplied).

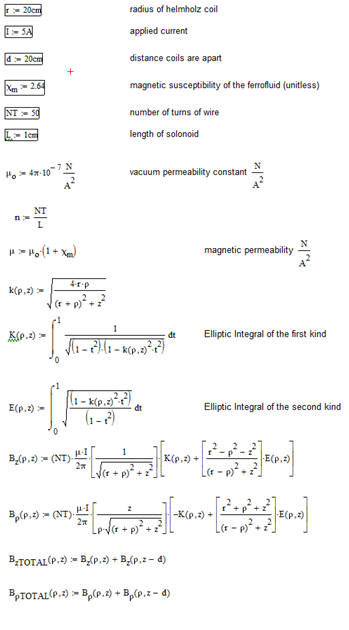

Electromagnetic Field

They dynamic response of the ferrofluid depends directly on the control parameter, the magnetic field. An understanding of the field magnitude and profile are essential in obtaining consistent and predictable results. The vector potential and field of a circular loop is given in Smythe [13] and elliptic integrals given by ref [14]. The model was expanded to account for two coils by adding an additional term and subtracting out the separation distance (d). The model was verified with parameters given in ref [2], by inputting the given coil dimensions and input current. The magnetic field strength of the model (8.179*10^3*A/m) closely matches the stated value of (8 *10^3*A/m). Figure 1 (B) shows a cross sectional view of the coils and vector field and the chosen reference origin “O” used to define the system. See Appendix for calculations. The exact parameters and number of turns of the Helmhotz-coil (Welch) have not yet been measured; however, a similar model, currently in production, from the same manufacturer was identified (Sargent-Welch, CENCO E/M Apparatus) and its values used to approximate the field conditions. Assuming 5 Amp input, a modest magnetic induction of 5.9 mT is expected at 90deg. The angle and magnitude did not deviate significantly within a 20cm diameter (< 3.3% from center to 10cm radius) (Figure 1, C). On the z-axis, the magnitude is consistent at < 1.5% change within 14cm of the midpoint of the coils (Figure 1, D). Note that the profile is reputed constant in φ, which is the angular direction about z and normal to z.

Figure 2: (a) Experimental Setup, (b) Magnetic Field Strength (A/m) of Helmholtz-coil, (c) Magnetic Induction (mT) profiles along rho, and along z (d)

Procedure

The prerequisite step of the experimental procedure is to fabricate the Teflon holder and assemble the experimental setup. Calibration will then be performed on the various measuring apparatuses; that is, tolerances on the magnetic field measurement will be determined and tests will be performed with the camera to determine a pixel to length relationship.

After proper calibration of experimental devices is achieved, the behavior of the ferrofluid under a static field will be explored. The field intensity will be gradually increased until the bifurcation point (spontaneous peak formation) is observed. Ideally this critical field value would be determined to two decimal places for each run and upwards of 15 runs would be performed in order to reduce the effect of any noise or random error in the results and to determine uncertainties. The empirical results will then be compared with the aforementioned model.

The second portion of the experiment will examine the dynamics of the ferrofluid in a static field at various temperatures. EFH-1 reacts hazardously with any type of exposed flame and accordingly safety considerations mandate some conductive form of heating [15]. Consequently, the heating apparatus used will be a hot plate. Furthermore, the experimental fluid becomes unresponsive to an field outside the range of -55 deg. to 200 deg. C and its flash point is 71.1 deg. C [15]. In light of the modest heating apparatus that will be used and safety considerations, an appropriate range for the investigation of temperature effects is 20-50 deg. C. The critical point of the fluid (with respect to varying field) would then be determined as in the previous segment iteratively while increasing the fluid temperature in 5 deg. C steps as measured with a thermometer. At each temperature step, the fluid will be allowed to heat for five minutes before any measurement is taken in order to minimize transient effects and to reduce internal temperature gradients as much as possible. Preferably, a minimum of 3 data acquisiton runs would be performed at each temperature step though the actual number of runs per temperature step will be determined by time constraints in the lab. A temperature model will then be developed from the empirical results. Time permitting, this model will then be verified by determing the critical field, \(H_c\), for a number of arbitrary temperatures (i.e. temperatures between 20-50 deg. C which are not integer multiples of 5 deg. C) and comparing the empirical observations with predictions of the model.

References

[1] V. STERR, ET AL., "ROLLING FERROFLUID DROP ON THE SURFACE OF A LIQUID," NEW JOURNAL OF PHYSICS, VOL. 10, P. 063029, 24 JUNE 2008 2008.

[2] T. MAHR AND I. REHBERG, "NONLINEAR DYNAMICS OF A SINGLE FERROFLUID-PEAK IN AN OSCILLATING MAGNETIC FIELD," PHYSICA D, VOL. 111, PP. 335-346, JAN 1 1998 1997.

[3] L. RUDNICK, SYNTHETICS, MINERAL OILS, AND BIO-BASED LUBRICANTS: CHEMISTRY AND TECHNOLOGY: CRC PRESS, 2005.

[4] C. RAU, ET AL., "STRONG TEMPERATURE-DEPENDENCE OF FERROMAGNETISM AT NI AND TB SURFACES DETERMINED WITH ECS," NUCLEAR INSTRUMENTS & METHODS IN PHYSICS RESEARCH SECTION B-BEAM INTERACTIONS WITH MATERIALS AND ATOMS, VOL. 13, PP. 594-596, MARCH 1, 1986 1986.

[5] D. VOLLATH, NANOMATERIALS: AN INTRODUCTION TO SYNTHESIS, PROPERTIES AND APPLICATIONS, 1 ED.: WILEY-VCH.

[6] M. D. COWLEY AND ROSENSWE.RE, "INTERFACIAL STABILITY OF A FERROMAGNETIC FLUID," JOURNAL OF FLUID MECHANICS, VOL. 30, PP. 671-&, 1967.

[7] J. MELCHER, FIELD-COUPLED SURFACE WAVES: MIT PRESS, 1963.

[8] R. KRAUß, ET AL., "PUMPING FLUID BY MAGNETIC SURFACE STRESS," NEW JOURNAL OF PHYSICS, VOL. 8, PP. 18-18, 2006.

[9] R. KRAUß, ET AL., "FLUID PUMPED BY MAGNETIC STRESS," APPLIED PHYSICS LETTERS, VOL. 86, P. 024102, 2005.

[10] T. MAHR AND I. REHBERG, "MAGNETIC FARADAY-INSTABILITY," EUROPHYSICS LETTERS, VOL. 43, PP. 23-28, JULY 1 1998 1998.

[11] A. BEETZ, ET AL., "RESPONSE OF A FERROFLUID TO TRAVELING-STRIPE FORCING," JOURNAL OF PHYSICS: CONDENSED MATTER, VOL. 20, P. 204109, 2008.

[12] R. E. ROSENSWEIG, FERROHYDRODYNAMICS: CAMBRIDGE UNIVERSITY PRESS, 1993.

[13] W. R. SMYTHE, STATIC AND DYNAMIC ELECTRICITY, 3RD ED.: A SUMMA BOOK, 1989.

[14] (OCTOBER 12). AVAILABLE: HTTP://KEISAN.CASIO.COM/KEISAN/ERROR.PHP

[15] FERROTEC. "EFH-1". MARCH 18, 2009. AVAILABLE: http://ferrofluid.ferrotec.com/downloads/efhmsds.pdf

group members: Amin Agha, Amir Hamid, Daniel Potter, Kipp Schoenwald

Appendix

- For (1), µ0 is a constant, E is the activation energy, R is the universal gas constant, and T is temperature. For (2), m is the magnetic moment of one particle, n is the number of particles, H is the magnetic field, k is Boltzmann’s constant, and T is temperature.